Products in this page

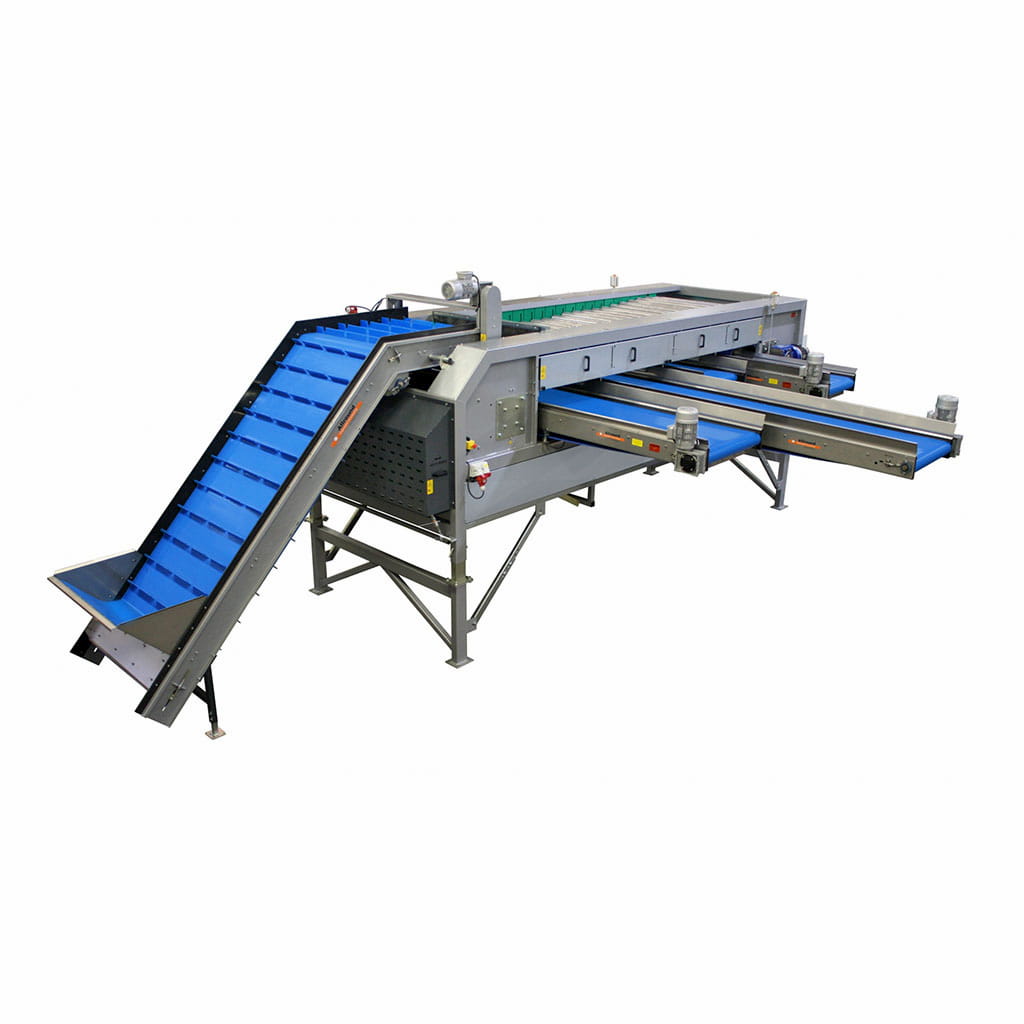

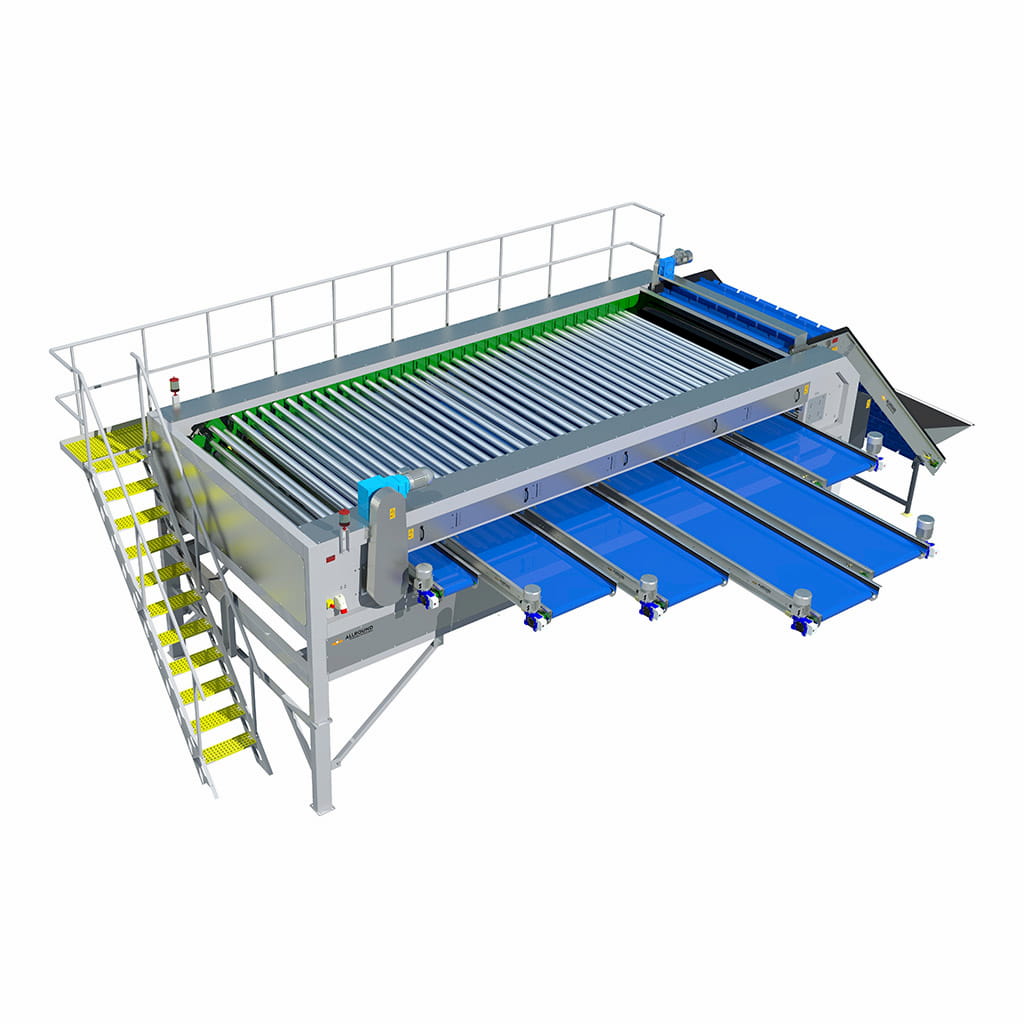

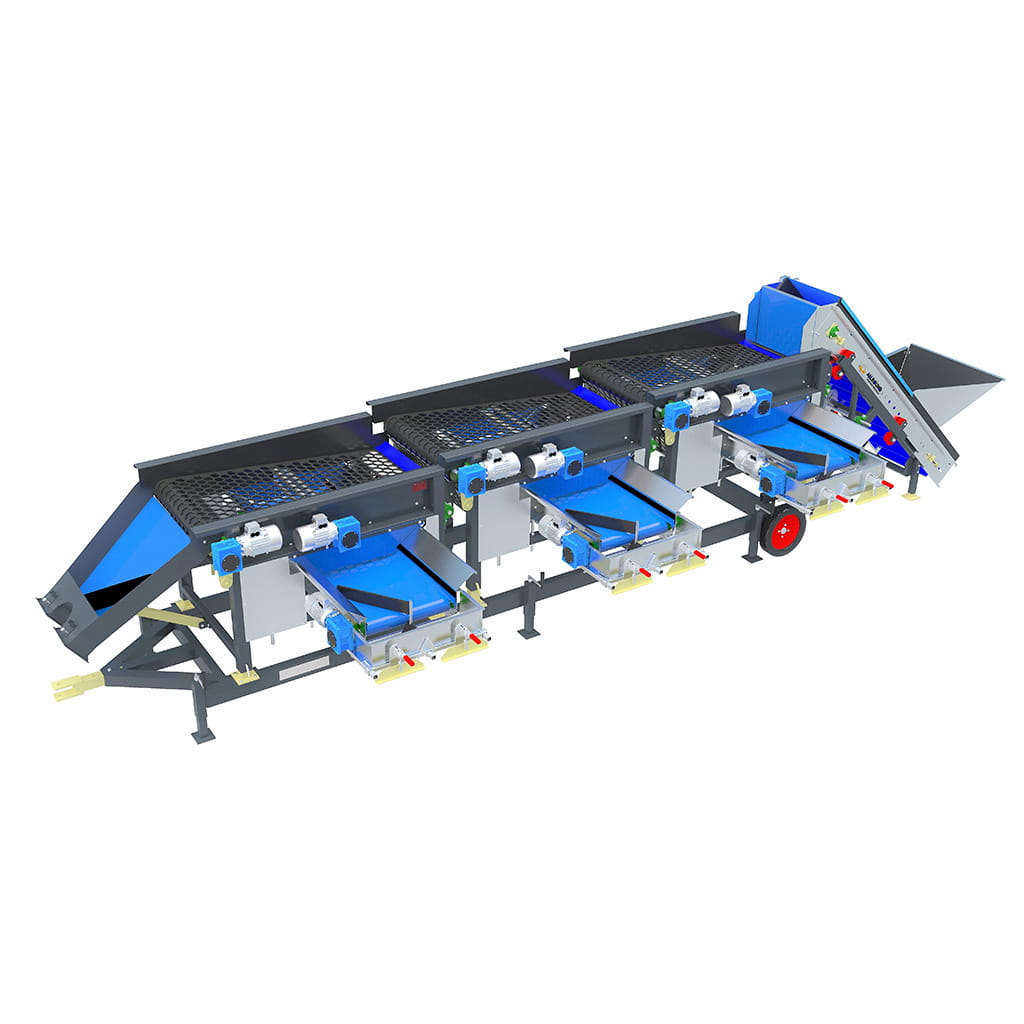

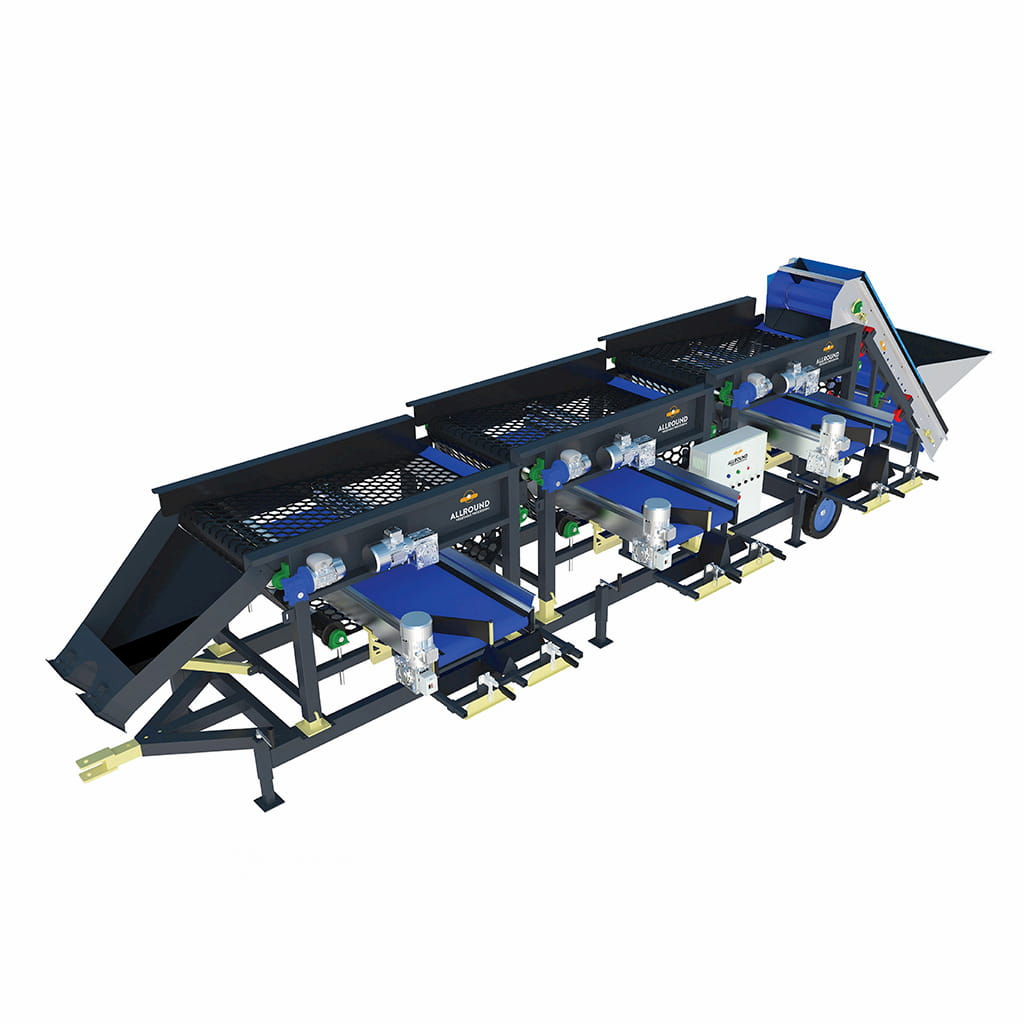

Radial Graders

The radial grader is fitted with laterally spaced stainless-steel grading rollers. The gap between the rollers increases gradually over the different grading phases. Conveyor belts, one for each grading size, are placed under the grading machine.

As the distance between the rollers increases over the size points, the second roller lowers in position to ensure that the product is well positioned between the rollers. The speed of the machine is adjustable by a frequency control unit, and the machine is equipped with a greasing system that ensure that the machine is always properly lubricated.

| Produce | R 80 | R 120 | R 150 | R 180 | R 200 | R 260 |

|---|---|---|---|---|---|---|

| Carrots | 3-4 | 8 | 14 | 20 | 25 | 35 |

| Baby Carrots | 3-4 | 5-8 | 10-12 | 14-16 | 18-22 | 25-30 |

| Red Beet | 5-6 | 8-10 | 14-16 | 22-30 | 35 | 45 |

| Potatoes | 6-7 | 8-10 | 15-18 | 22-30 | 35-40 | 45-50 |

| Parsnips | 2-3 | 3-4 | 6-8 | 12 | 18 | 24 |

| Onions | 6-7 | 8-10 | 15-18 | 22-30 | 35-40 | 60 |

| Set Onions | 3-5 | 6-8 | 10-12 | 14-16 | 18-22 | 25-30 |

Note: All capacities are in Tons/hour

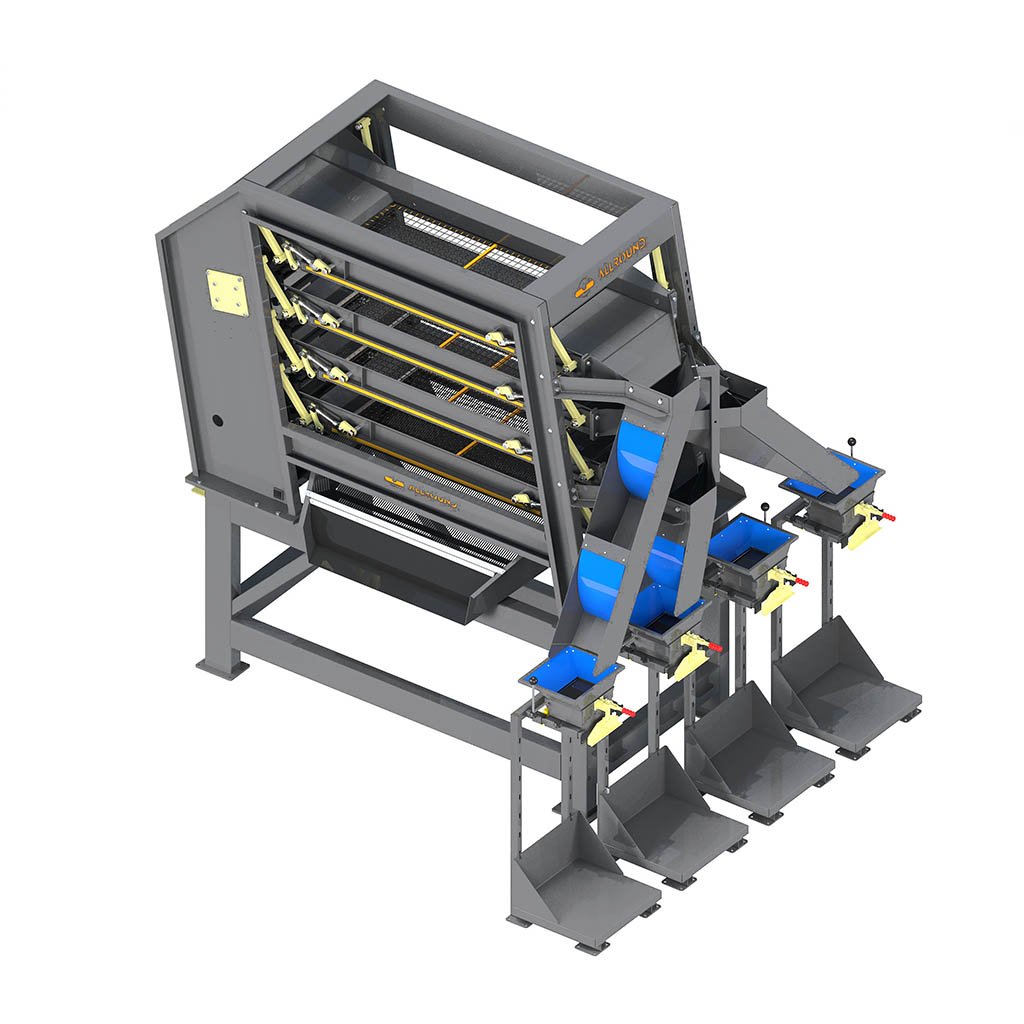

Shake Graders

The shake grader is specially designed to grade potatoes according to their square size. The potatoes are fed on to the top sieve of the machine. The sieves shake at various frequencies causing the potatoes to move along them and drop in the slot that matches their size.

The sieves' motions are triggered by the front-side motor of the machine. This engine drives crankshaft that causes the sieves to shake. The machine's motor is a computer-controlled frequency inverter that enables the sieves to shake at multiple sequential frequencies.

| Produce | SG 60 | SG 80 | SG 120 |

|---|---|---|---|

| Table/Industrial Potatoes | 4-6 | 12-15 | 25-30 |

| Seed Potatoes | 3-4 | 10-12 | 20-25 |

| Onions | 3-4 | 8-10 | 18-20 |

Note: All capacities are in Tons/hour

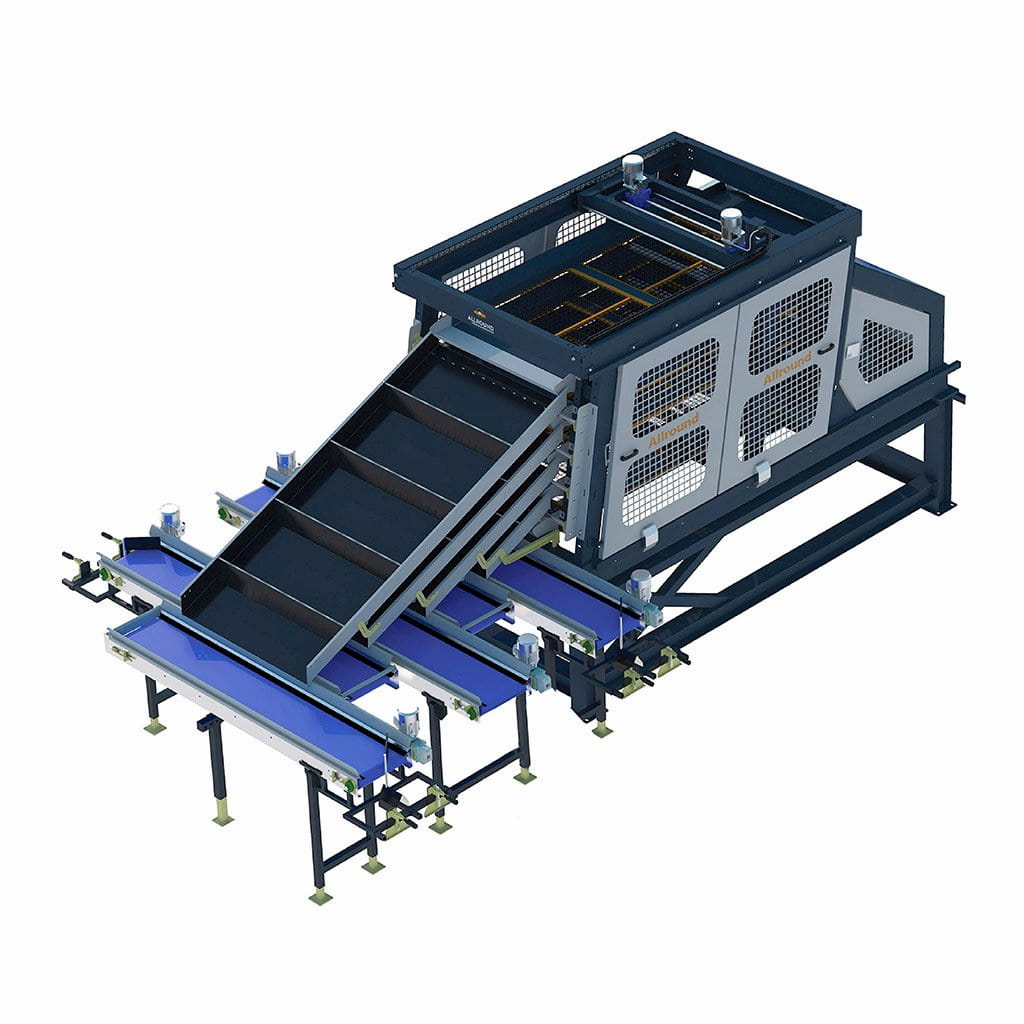

Screen Sizer

The screen sizer is designed to grade produce according to their square or hexagonal size. The machine has a vibrating rubber bed with openings. If the product is smaller than the opening, it falls onto a belt beneath it.

| Produce | SS 90 | SS 120 | SS 180 |

|---|---|---|---|

| Potatoes | 8-10 | 12-14 | 18-20 |

| Onions | 6-8 | 10-12 | 15-18 |

| Seed Potatoes | 5-8 | 10-12 | 15-18 |

Note: All capacities are in Tons/hour

| Specs | SS 90 | SS 120 | SS 180 |

|---|---|---|---|

| Length (mm) | Depending on Sections | Depending on Sections | Depending on Sections |

| Width (mm) | 1100 | 1400 | 2000 |

| Screen Width (mm) | 900 | 1200 | 1800 |

| Drawing | View | - | - |

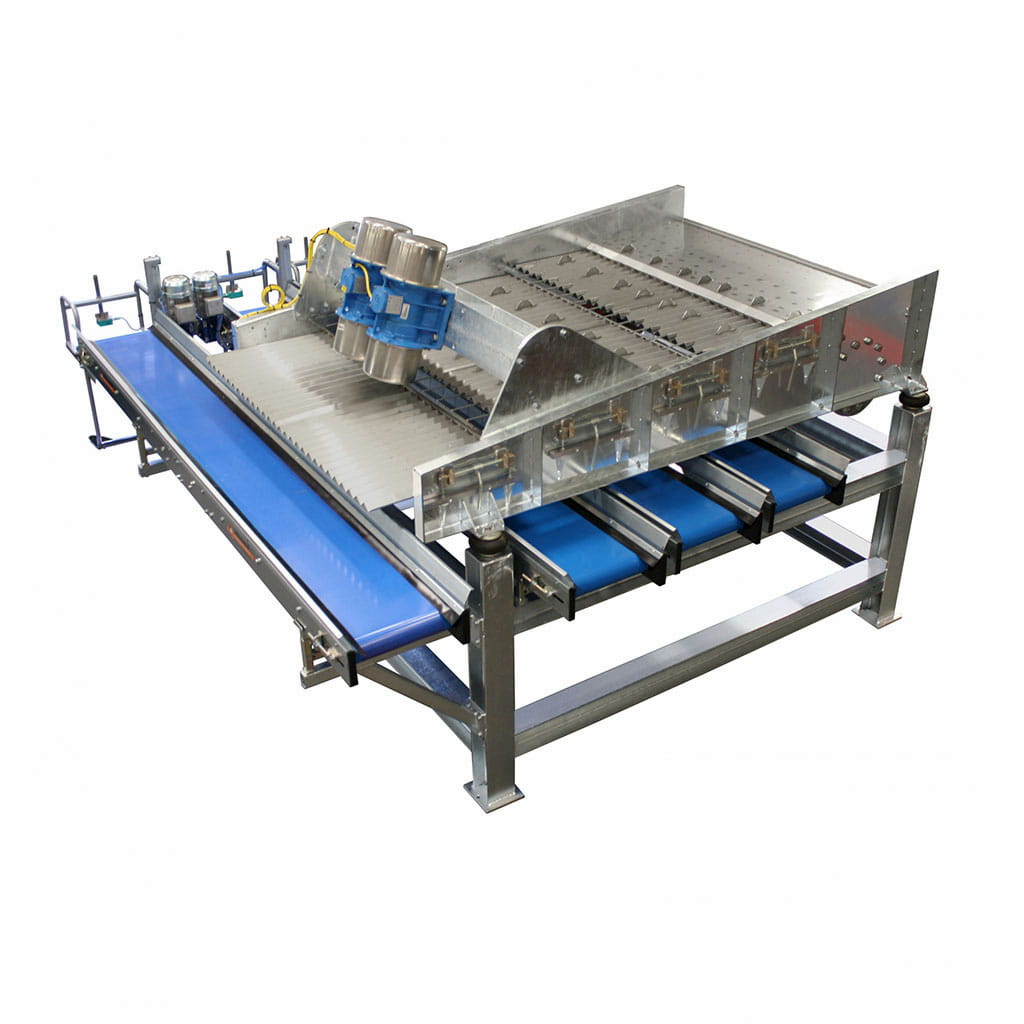

Chunk / Length Grader

The chunk/length grader is especially made for sorting carrots and similar shaped products. The machine is designed to filter out oversized carrots, because they do not fit for packaging, and to take out the broken and undersized carrots. This machine can be delivered with various grading sizes and capacities.

The stainless-steel bed ensures that the machine is food grade and safe to use for your products. The frame is made of galvanized steel to guarantee a long service life for the machine.

| Model | Capacity |

|---|---|

| L 100 | 2-3 |

| L 120 | 3-5 |

| L 150 | 4-7 |

| L 180 | 6-9 |

| L 200 | 8-11 |

Note: All capacities are in Tons/hour

| Specs | L 100 | L 120 | L 150 | L 180 | L 200 |

|---|---|---|---|---|---|

| Length (mm) | Depending on Sections | Depending on Sections | Depending on Sections | Depending on Sections | Depending on Sections |

| Width (mm) | 1250 | 1450 | 1750 | 2150 | 2250 |

| Bed Width (mm) | 1000 | 1200 | 1500 | 1800 | 2000 |

| Drawing | View | View | View | View | View |

String Grader

The string grader is built to pre-grade the undersized produce or stones to separate oversized produce like red beet. The unit has a minimum grading size of 40mm and a maximum size of 70mm.

| Specs | PS 70-17 |

|---|---|

| Width Belt (mm) | 1200 |

| Belts | 17 |

| Minimum Grading Size (mm) | 50 |

| Maximum Grading Size (mm) | 75 |