Products in this page

Washing Machines

The washing machines are designed to wash your produce in a lavatory water tank. The water used in the pump is recirculated in this water tank and reused. The machine's washing drum agitates the produce inside the tank to deliver optimal cleaning results.

| Light Soil | 300 Series | 450 Series | 500 Series |

|---|---|---|---|

| Carrots | 3.5 | 9 | 21 |

| Baby Carrots | 3 | 8 | 14 |

| Potatoes | 10 | 17 | 16 |

| Parsnips | 3 | 6 | 10 |

| Celeriac | 3.5 | 12 | 16 |

| Red Beet | 3.5 | 9 | 19 |

| Heavy Soil | 300 Series | 450 Series | 500 Series |

|---|---|---|---|

| Carrots | 2.5 | 6 | 18 |

| Baby Carrots | 2 | 4 | 7 |

| Potatoes | 7 | 14 | 28 |

| Parsnips | 2 | 5 | 9 |

| Celeriac | 3 | 6 | 8 |

| Red Beet | 3 | 6 | 16 |

Note: All capacities are in Tons/hour

| Specs | U 600 | U 500 | U 450 | U 300 | U 170 | UK 450 | UK 300 |

|---|---|---|---|---|---|---|---|

| Drum Length (mm) | 6000 | 5000 | 4500 | 3000 | 1700 | 4500 | 3000 |

| Drum Diameter (mm) | 1900 | 1600 | 1200 | 1200 | 800 | 1200 | 1000 |

| Drum Material | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| Total Length (mm) | 10440 | 9440 | 8400 | 6400 | 3700 | 8050 | 6400 |

| Drawing | - | View | View | View | - | View | View |

| Specs | PDK 500 | PDK 450 | PDK 300 | C 300 |

|---|---|---|---|---|

| Drum Length (mm) | 5000 | 4500 | 3000 | 3000 |

| Drum Diameter (mm) | 1600 | 1200 | 1000 | 1000 |

| Stainless Steel | Drum Material | Stainless Steel | Stainless Steel | Stainless Steel |

| Total Length (mm) | 11000 | 8670 | 6310 | 3660 |

| Drawing | - | View | View | - |

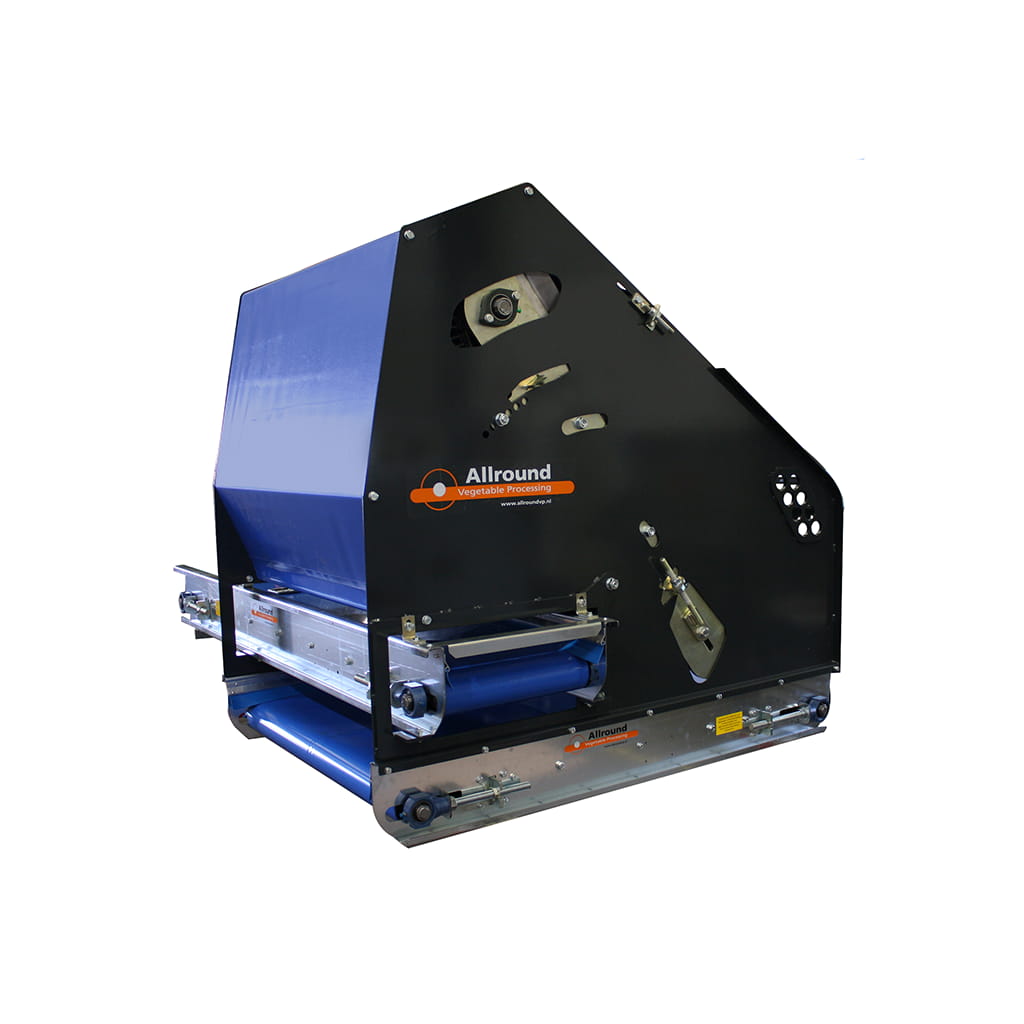

Skin Separator

The skin separator is intended to remove any loose pieces from the product, such as leaves, pieces of skin or branches. The machine separates the pieces from the product through a floating waste outlet based on the principle that the produce is heavier than the pieces to be removed.

In addition, at the bottom of the machine is a cleaning door, which can be opened and closed to clean out any residues. A web belt with rubber cleats carries the product out of the unit ensuring that water loss in the system is minimal.

| Skin Separators | |

|---|---|

| Capacity | 25-80 |

Note: All capacities are in Tons/hour

Destoner

The destoner is the ideal machine to remove dirt from the surface of your vegetables.

The destoner can be integrated in a washing machine to combine the advantages of both.

| D 110 | D 150 | D 200 | |

|---|---|---|---|

| Capacity | 10-15 | 25 | 45 |

Note: All capacities are in Tons/hour

Onion Topper

The onion toppers are designed to top the onion’s tail. This is achieved by spinning knifes under vibrating sieves which cause the cause the onion’s tail to fall through the sieves, and then are cut off by the knife. A simple quick lock system allows you to easily change the sieves whenever necessary.

The onion toppers are designed for delicate handling of the produce and are safe to use. Regular cleaning of the knives and propeller is important for long term efficiency.

| Produce | A1 | A2 | A3 |

|---|---|---|---|

| Onions | 3-4 | 6-8 | 9-12 |

| Set Onions | 2 | 4 | 6 |

Note: All capacities are in Tons/hour

Leaf Separator

The leaf separator, as the name suggests, is useful for delicately separating leaves from the carrot. This is achieved by a rotating belt to which the leaves attach. The rotating belt is placed at a steep angle, leading to the leaves being transported upwards and the heavier product falling down.

The product can be transported via a conveyor belt or directly into a machine after the carrots are separated from the leaves.

Brushing Machine

The brushing machine is built for cleaning produce, like onions, tomatoes, apples, and potatoes, using wave-shaped brushes. The produce push each other in masses to move forward, and below the brushes, a conveyor belt can be placed to collect any dust or debris.

We offer brushes with various hardness, depending on the product being processed.

VB = Vegetable brushing machine

BR = Potato brushing machine

| Produce | 60-9 | 100-13 | 120-15 |

|---|---|---|---|

| Potatoes | 6 | 10 | 10-13 |

Note: All capacities are in Tons/hour

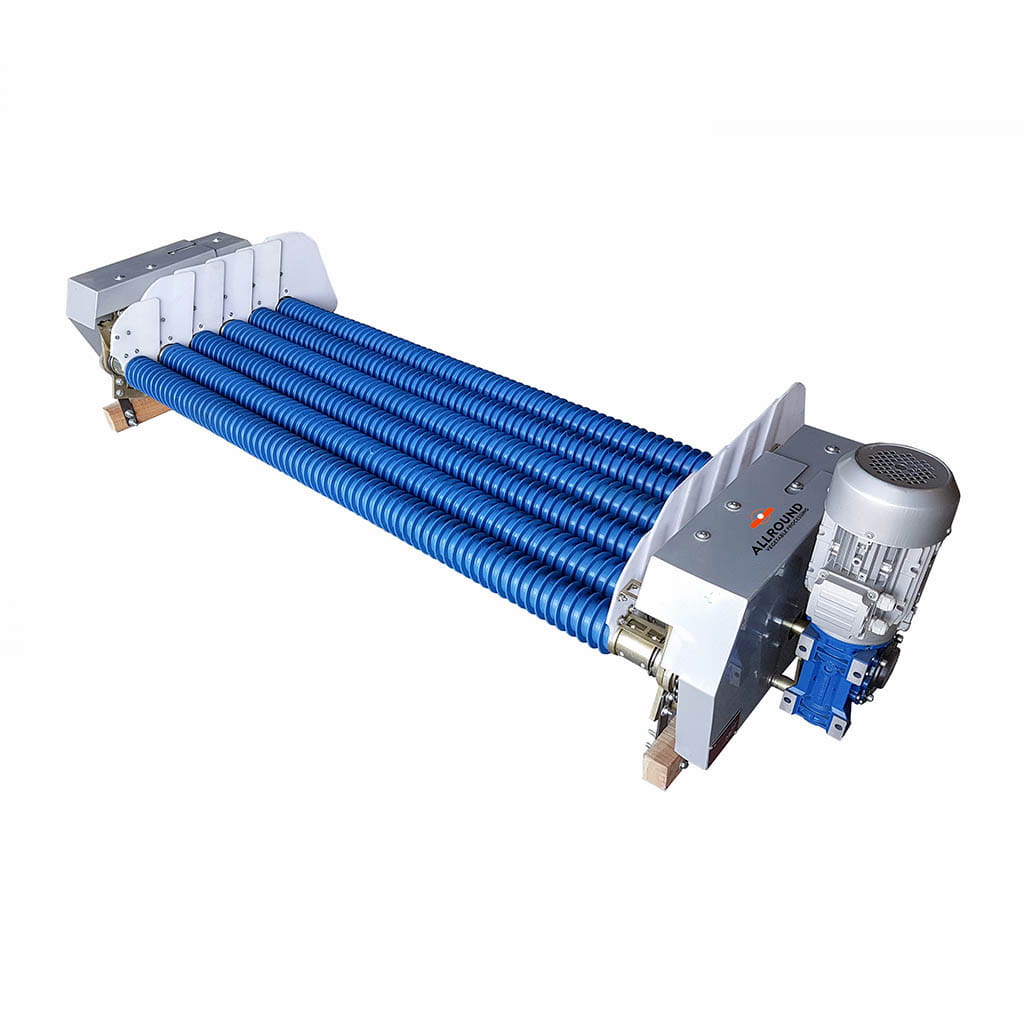

Finger Roller Set

The finger roller sets are designed to remove any loose skin and dirt on the produce. This gentle and efficient pre-cleaning process helps improve the capacity of the whole line by greatly reducing the amount of dirt that hinder the movement in the other machines.

We offer a variety of finger roller sets:

1. Stand-alone machines.

These stand-alone finger roller sets can be placed after a conveying belt. They are available in different sizes.

2. Mounted to a hopper

We also offer finger roller sets which can be mounted on a hopper. The size of the finger roller sets depends on the size of the hopper itself.

Available in customized lengths, widths, and roller types depending on customer's needs.

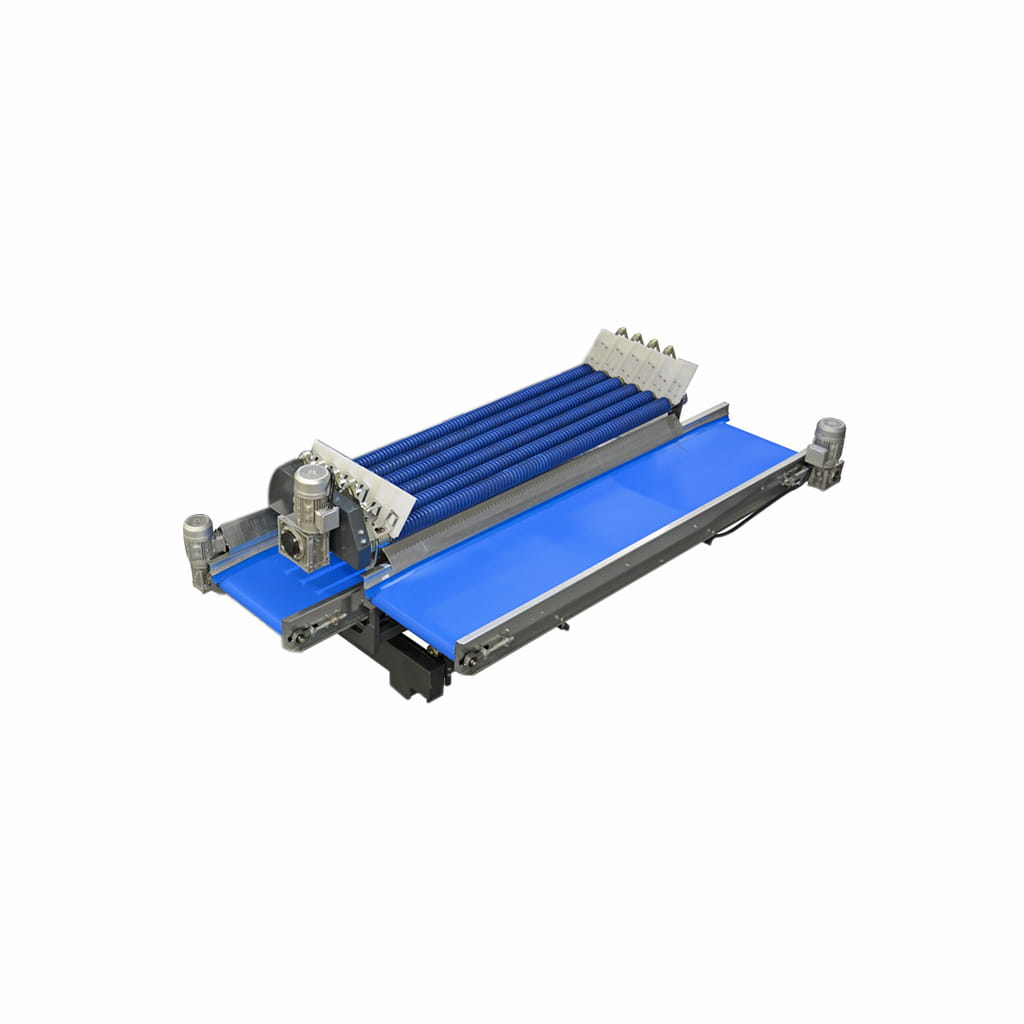

Adjustable Roller Sets

The adjustable roller sets are intended for pre-cleaning and pre-grading. They can be mounted on all types of hoppers that we offer.

They are available with:

- Stainless steel rollers

- Diabolic rollers

- Spiral rollers

Available in customized lengths, widths, and roller types depending on customer's needs.